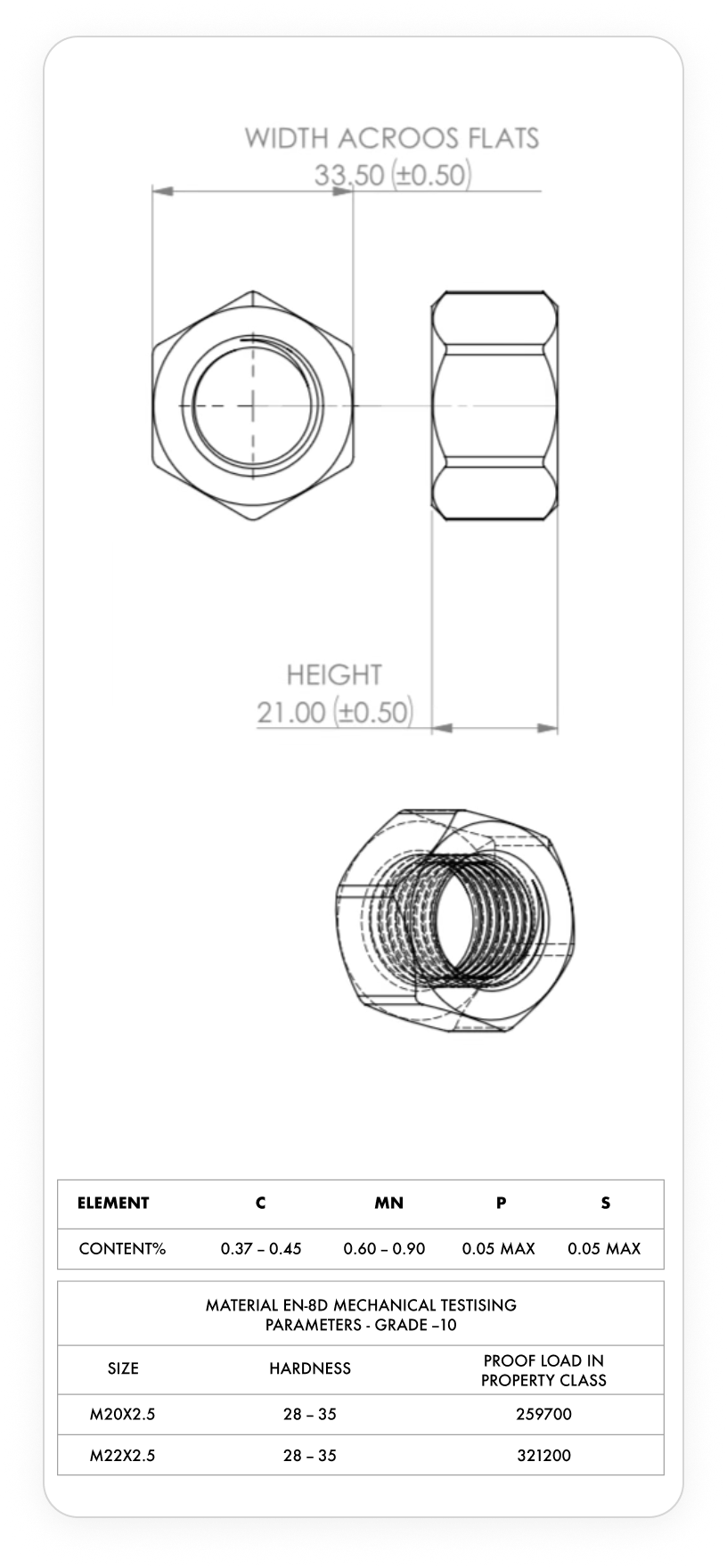

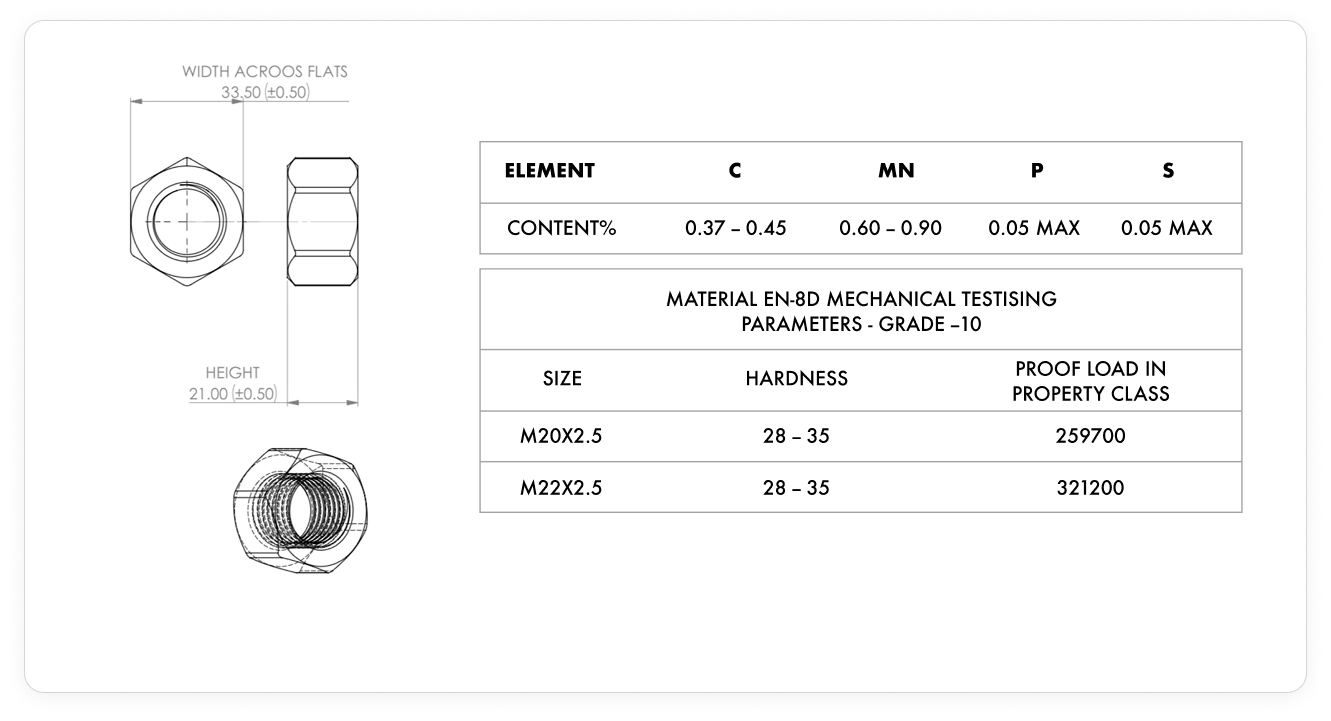

Forging Range

- Hammer & press capacity up to 200T

- Billet Ø up to 180 mm; bars to 6 m

- Materials: CS/MS, alloy steels, SS, copper alloys

Vikastools

We design and manufacture precision‑forged components, build special‑purpose machines, and commission heat treatment plants for demanding industries. From nuts, anchor plates, and tension rods for sleeper projects to turnkey production lines—we deliver quality, speed, and reliability.

Request a Quote

Share drawings/specs. We assess manufacturability, tooling and compliance.

Die design, FEA, process sheets, control plan, and buy‑off with customer.

Trial lots, dimensional reports, metallurgy and functional validation.

Production with SPC, packaging, logistics & after‑sales support.

Vikastools

We design and manufacture precision‑forged components, build special‑purpose machines, and commission heat treatment plants for demanding industries. From nuts, anchor plates, and tension rods for sleeper projects to turnkey production lines—we deliver quality, speed, and reliability.

Request a Quote

Explore Services

Share drawings/specs. We assess manufacturability, tooling and compliance.

Die design, FEA, process sheets, control plan, and buy‑off with customer.

Trial lots, dimensional reports, metallurgy and functional validation.

Production with SPC, packaging, logistics & after‑sales support.